ParaDry® Lift Configurations

The optimal hoist configuration for any parachute drying tower involves careful consideration of parachute types, dimensions, quantity, weight, tower layout, and production service cycles. Our detailed preliminary design process ensures that ParaDry® Systems lift equipment and tower solutions will provide high-volume production efficiency and operational dependability in a clean, safe working environment. All our lifts are designed to handle the high heat, humidity, and rigorous use of a paraloft tower.

To best address your operational needs, ParaDry®Systems offers two hoist types: the ParaLine™ and the ParaDrum™.

ParaLine™ Parachute Lifts

- ParaLine™ lifts utilize multiple helically grooved in-line cable drums, which are connected by a common drive shaft, to suspend a horizontal lift bar. Lift hooks are spaced along the lift bar as needed. This design is compact without sacrificing power.

ParaDrum™ Parachute Lifts

- ParaDrum™ lifts utilize one helically grooved cable drum to spool out multiple lift lines into separate loft sheaves when structural configurations require individual lift hooks in lieu of a lift bar.

“It is the best product on the market today. It’s really one of the best looking and operating shaft drive units I’ve ever installed and used without fault!”

— Gregory Keatley, Veteran Rigger

The system has performed flawlessly, and there have been no malfunctions since installation.

I highly recommend ParaDry® Systems and would not hesitate to subcontract with InterAmerica again.

– Brandon Warner, Project Manager | Thomas May Construction

ParaRam™ Parachute Lifts

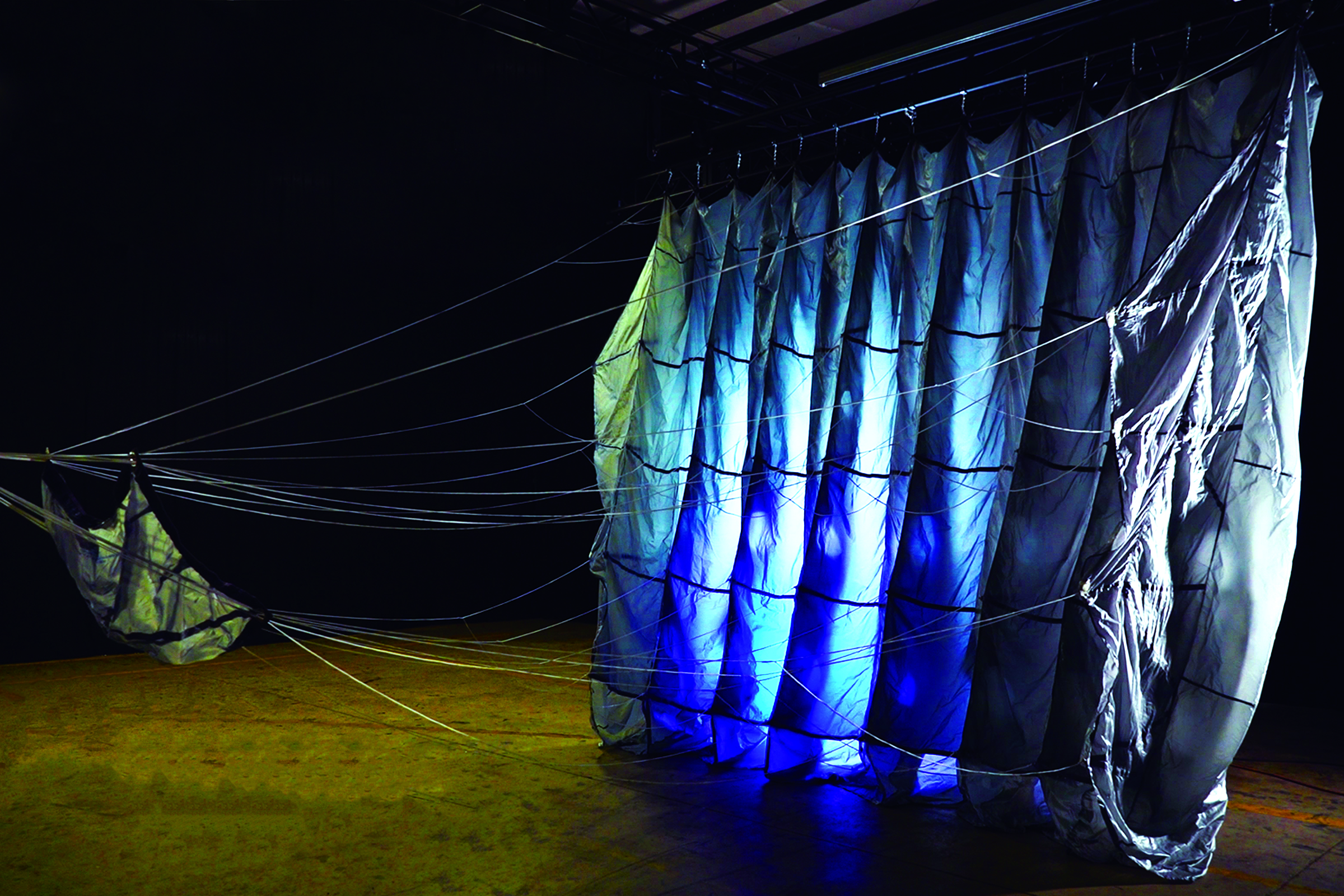

Within the our military Special Forces, there is rapidly growing use of Ram-Air parachutes, which consist of a rectangular canopy with individual air cells for increased safety and greater maneuverability at high or low altitudes. For effective drying and servicing, Ram-Air chutes must be fastened at every tail rib point along the rear trailing edge of the canopy and suspended vertically.

ParaRam™ lifts were specifically designed for this unique suspension requirement of the Ram-Air chutes. This is a relatively light-duty and uncomplicated hoist that utilizes simplified plug-and-play motorized control components powered from standard wall outlets and activated by a hand-held remote control pendant.

- Includes a specialized lift bar with integral clamps with adjustable spacing to accommodate various Ram-Air canopy models.

- ParaRam lift bars can be suspended below roof framing steel in a parachute packing room or attach directly to the standard parachute lifts of a drying tower.

The experience of working with IA Stage is educational. As one of the architects working on this project, we only had a preliminary concept of how the hoist system should fit and operate inside the building. IA Stage went beyond our expectations and explained every detail.

– Zoran Aleksic, R.A., NCARB, Project Architect | Hanson | Camp Blanding Joint Training Center

ParaDry® Expeditionary Tower–

The Expeditionary Parachute Drying Tower – an integral part of our parachute maintenance and services – is a temporary, mobile, and fully operational paraloft facility, combining standard elements typically utilized within a fixed-construction paraloft tower, with the rugged flexibility required for repeated relocation to alternate sites. In other words, the Expeditionary Tower brings parachute maintenance products and services right into the field.

- Tower Structure — Single temporary truss structure designed for ease of set up and removal along with related infrastructure systems. Expeditionary structure to be approximately (30’ x 40’) x 50’ high, including covered ridgeline roof configuration. Tower structure is designed for erection and operation on excavated ground with gravel surface. Structure comprised of non-hardened exterior and interior structural supports, including covered roof component, with Lightning Protection.

- Electrical Power Generator — 100% Prime Generator power. LP gas fueled mobile configuration on trailer with an LP tank source.

- Heaters/Blowers — Internal HVAC system for drying suspended wet parachutes shall be LP gas fueled, with ducts and diffusers for circulation of heated airflow for parachute drying only (no comfort systems are included). Performance objective is to air-dry fifty (50 wet T-11 parachutes in 24-hr time period.

- Internal Lighting and power outlets are included.

- Enclosure Walls — Heavy-duty nylon fabric vertical wall coverings with crescent cut-outs to reduce wind resistance and permit limited airflow out from the facility.

- ParaDry® Parachute Lift System and Controls — comprised of four (4) separate PL-1500 Parachute Lifts to independently raise, suspend, and lower up to approximately fifty (50) wet T-11 personnel parachutes simultaneously.

The hoist way system is the heart of any parachute drying tower project. No matter how effectively and efficiently the other functions may operate, if the hoist way system doesn’t work as intended . . . the project is a failure. As lead architect for the Camp Blanding Parachute Drying Tower, I took extra time to research the right type of hoist way system. The ParaDry®System not only satisfied the project requirements, it was the only system within the budget. InterAmerica is my choice for all future Parachute Drying Tower projects.

– D. Brent Sauser, AIA, LEED AP | President | dbsArchitectsPLLC

Rigging Inspection & Review

Adhering to recommended industry standards is a great way to limit owner liability in the event of an accident and to protect your greatest asset – your personnel. Make annual rigging inspections part of your risk management/accident prevention program. We offer in-depth inspections of all overhead lift systems as part of our line of parachute maintenance products and services.

Inspections include a thorough visual review and overall assessment of your facility’s parachute lift components, including gearmotors, control systems, suspension components, and associated rigging hardware. You will receive a written report with photo documentation of the inspection, along with comprehensive recommendations for maintenance, repairs, and/or upgrades. Budgetary pricing for recommended repairs and upgrades will include renovation options for subsequent safety renovation.

The first and best strategy for hazard prevention is to control the hazard at its source. Keep your staff safe by identifying and correcting hazards before accidents happen.